Diagnostics of heating surface tubes of steam and hot-water boilers

Inspection is carried out on the boiler shut down for the repairs. Fig.1

shows the scheme of the waterwall tubes inspection using a specialized

magnetometric instrument - the TSC-type tester of stress concentration.

Fig.1. The scheme of waterwall tubes

inspection: 1 - scanning device with the length measuring sensor; 2, 3 -

flux-gate transducers; 4 - connection cable; 5 - the TSC-type instrument.

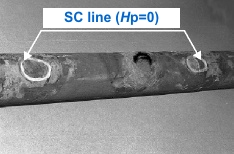

Fig.2, a shows the fragment of the inspection results in a SC zone

on the waterwall tube of the boiler furnace gasproof panel. Fig.2, b shows the characteristic damaging of the gasproof panel waterwall tube.

|

|

Fig.2a. The results of

inspection in a SC zone on the waterwall tube of the boiler furnace

gasproof panel. |

Fig.2b. Characteristic

damaging of the gasproof panel waterwall tube. |

Fig.3 shows the fragment of the corrosion pit detection by the character of

the residual magnetization field Hp distribution along the fire generatrix of the

tube.

Fig.3. Detection of the corrosion pit by the

character of the residual magnetization field Hp distribution: 1 - pit area.

Fig.4 presents the example of the distribution of the normal (Hpy) and the tangential

(Hpx)

components of the self-magnetic leakage field (SMLF) recorded along the external

generatrix of the boiler tube operating in conditions of the lack of

self-compensation.

Fig.4. The distribution of the normal

(Hpy) and the

tangential (Hpx) components of the

self-magnetic leakage field (SMLF).

The suggested method of diagnostics allows carrying out the mass inspection

of welded butt joints on HS tubes and in the units of tubes and coils attachment

to collectors without metal dressing. The method may be applied effectively for

detection of SC zones on superheater tubes made of pearlitic and austenite steel

grades. Based on the results of the inspection using the metal magnetic memory

method, it is possible to perform cutting out of representative tube specimens

for the analysis of the metal’s state, determination of the amount and the

quality of internal deposits. The method allows carrying out simultaneously flaw

detection and diagnostics with revealing of the reasons of SC zones and damages

occurrence.

There is an experience of the MMM method application for early diagnostics of

gasproof panel tubes damages and improvement of the effectiveness of their

repairs. It is suggested, using the results if the inspection by the MMM method,

to remove the reasons of SC zones occurrence during the boilers repairs by means

of ensuring the self-compensation of tubes. Performing the metal’s external

surface grinding in SC zones is also an effective measure.

The developed diagnostic method belongs to quick methods and allows

inspecting all the tubes of the high-power boiler furnace chamber within 5-6

working days.

The "Methodic Guideline for engineering diagnostics of steam and hot-water

boiler heating surface tubes using the magnetic memory of metal" (GD

34.17.446-97) was approved by "Russian UES" RJSC and agreed with the Russian

State Technical Supervision Body (Gosgortechnadzor). This guidance document is

mandatory for application at the electric power engineering industry enterprises

and may be applied at the enterprises of other industries, owning the boilers,

which are subject to supervision of the Russian State Technical Supervision

Body. In 2002 this guidance document was supplemented and revised taking into

account the accumulated experience. |